York HL8B Installation Manual Page 15

- Page / 16

- Table of contents

- BOOKMARKS

Rated. / 5. Based on customer reviews

501055-UIM-B-1009

Johnson Controls Unitary Products 15

SECTION VIII: SYSTEM OPERATION

For more information on the control operation, refer to “Operation

Instructions - DEMAND DEFROST CONTROL BOARD in this Booklet.

REQUIRED CONTROL SETUP

1. Consult system wiring diagram to determine proper thermostat wir-

ing for your system.

2. If hot heat pump configuration is desired, change HOT HEAT

PUMP jumper to ON position. This setting MUST be set on the

defrost board.

3. If installation includes a fossil fuel furnace, change FUEL jumper to

ON position. This setting MUST be set on the defrost board.

4. Set low temperature cutout (LTCO), balance point (BP), switch

point (SP), and Y2 Lock jumpers as desired. These settings may be

modified by communicating thermostat.

5. Verify proper system functionality. Confirm room thermostat opera-

tion including fault code display capability.

6. Upon completion of installation, verify that no fault codes are stored

in memory. Clear the fault code memory if necessary.

DEFROST OPERATION

The following defrost curve selection jumper positions are set from fac-

tory.

INDICATIONS OF PROPER OPERATION

Cooling

Cooling operation is the same as any conventional air conditioning unit.

1. The outdoor fan should be running, with warm air being discharged

from the top of the unit.

2. The indoor blower (furnace or air handler) will be operating, dis-

charging cool air from the ducts. Coils or other parts in the air cir-

cuit should be cleaned as often as necessary to keep the unit

clean. Use a brush, vacuum cleaner attachment, or other suitable

means.

3. The vapor line at the outdoor unit will feel cool to the touch.

4. The liquid line at the outdoor unit will feel warm to the touch.

Heating

Indications of proper Heating operation is as follows:

1. The outdoor fan should be running, with cool air being discharged

from the top of the unit.

2. The indoor blower (furnace or air handler) will be operating, dis-

charging warm air from the ducts.

3. The vapor line at the outdoor unit will feel warm to the touch.

4. The liquid line at the outdoor unit will feel cool to the touch.

SECTION IX: INSTRUCTING THE OWNER

Assist owner with processing warranty cards and/or online registration.

Review Owners Guide and provide a copy to the owner and guidance

on proper operation and maintenance. Instruct the owner or the opera-

tor how to start, stop and adjust temperature setting.

When applicable, instruct the owner that the compressor is equipped

with a crankcase heater to prevent the migration of refrigerant to the

compressor during the “OFF” cycle. The heater is energized only when

the unit is not running. If the main switch is disconnected for long peri-

ods of shut down, do not attempt to start the unit until 8 hours after the

switch has been connected. This will allow sufficient time for all liquid

refrigerant to be driven out of the compressor.

The installer should also instruct the owner on proper operation and

maintenance of all other system components.

MAINTENANCE

1. Dirt should not be allowed to accumulate on the outdoor coils or

other parts in the air circuit. Clean as often as necessary to keep

the unit clean. Use a brush, vacuum cleaner attachment, or other

suitable means.

2. The outdoor fan motor is permanently lubricated and does not

require periodic oiling.

3. If the coil needs to be cleaned, it should be washed with Calgon

Coilclean (mix one part Coilclean to seven parts water). Allow solu-

tion to remain on coil for 30 minutes before rinsing with clean water.

Solution should not be permitted to come in contact with painted

surfaces.

4. Refer to the furnace or air handler instructions for filter and blower

motor maintenance.

5. The indoor coil and drain pan should be inspected and cleaned reg-

ularly to prevent odors and assure proper drainage.

The following steps must be taken at the time of installation to

insure proper system operation.

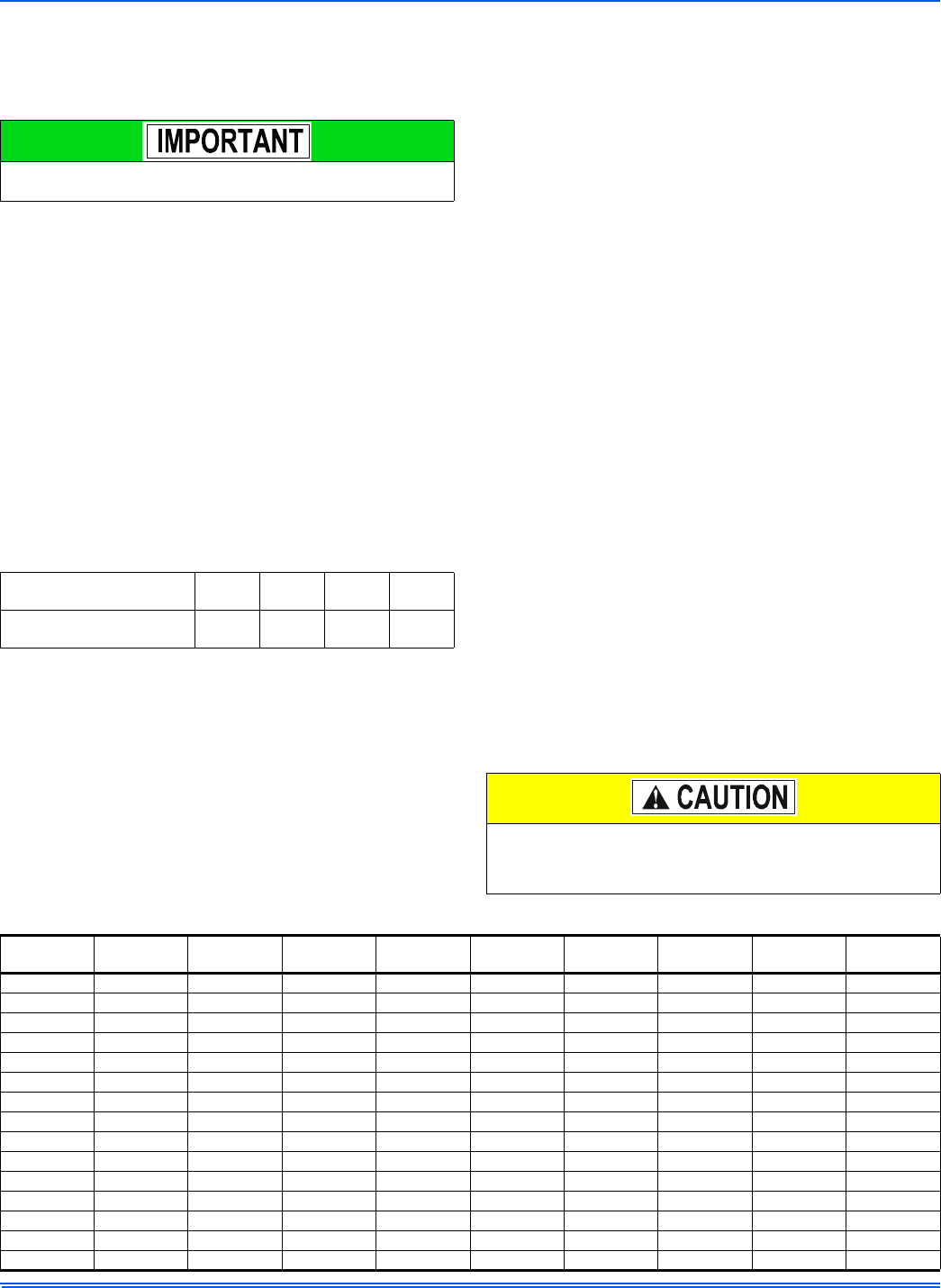

TABLE 1:

Defrost Initiate Curves

Defrost Curve Selection

Jumper Position

1234

Heat Pump Model

2-Ton

2.5-Ton

4-Ton

5-Ton

3-Ton

3.5-Ton

1.5-Ton

IT IS UNLAWFUL TO KNOWINGLY VENT, RELEASE OR DIS-

CHARGE REFRIGERANT INTO THE OPEN AIR DURING

REPAIR, SERVICE, MAINTENANCE OR THE FINAL DISPOSAL

OF THIS UNIT.

TABLE 2:

R-410A Saturation Properties

TEMP. °F

PRESSURE

PSIG

TEMP. °F

PRESSURE

PSIG

TEMP. °F

PRESSURE

PSIG

TEMP. °F

PRESSURE

PSIG

TEMP. °F

PRESSURE

PSIG

45 129.70 60 169.60 75 217.40 90 274.10 105 340.50

46 132.20 61 172.60 76 220.90 91 278.20 106 345.30

47 134.60 62 175.50 77 224.40 92 282.30 107 350.10

48 137.10 63 178.50 78 228.00 93 286.50 108 355.00

49 139.60 64 181.60 79 231.60 94 290.80 109 360.00

50 142.20 65 184.60 80 235.30 95 295.10 110 365.00

51 144.80 66 187.70 81 239.00 96 299.40 111 370.00

52 147.40 67 190.90 82 242.70 97 303.80 112 375.10

53 150.10 68 194.10 83 246.50 98 308.20 113 380.20

54 152.80 69 197.30 84 250.30 99 312.70 114 385.40

55 155.50 70 200.60 85 254.10 100 317.20 115 390.70

56 158.20 71 203.90 86 258.00 101 321.80 116 396.00

57 161.00 72 207.20 87 262.00 102 326.40 117 401.30

58 163.90 73 210.60 88 266.00 103 331.00 118 406.70

59 166.70 74 214.00 89 270.00 104 335.70 119 412.20

(8 pages)

(8 pages)

Comments to this Manuals